Maintenance Entities

Maintenance Entities are used to describe and encapsulate all the work to be performed in a given entity. It is possible to set up as many maintenance entities as required for a given Model, Site or Equipment record. An example of an Entity might be a 10,000 mile/km service, 20,000 mile/km service, or Monthly Preventative Maintenance, Quarterly Preventative Maintenance, Yearly Preventative Maintenance and so on. Each Maintenance Entity would then contain the Conditions and Tasks applicable for that entity.

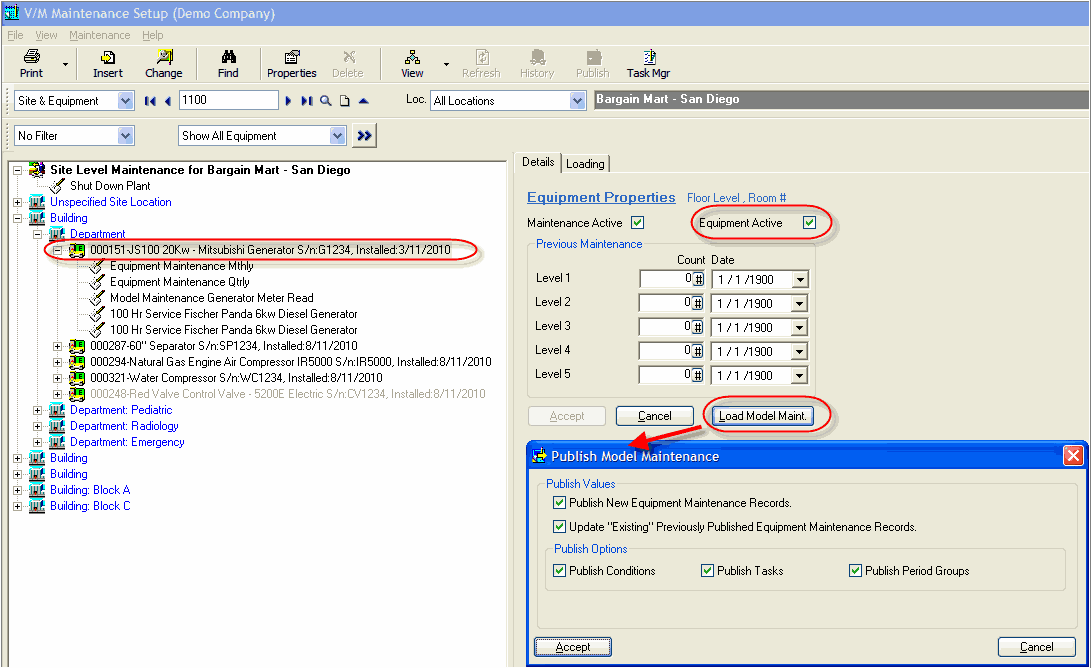

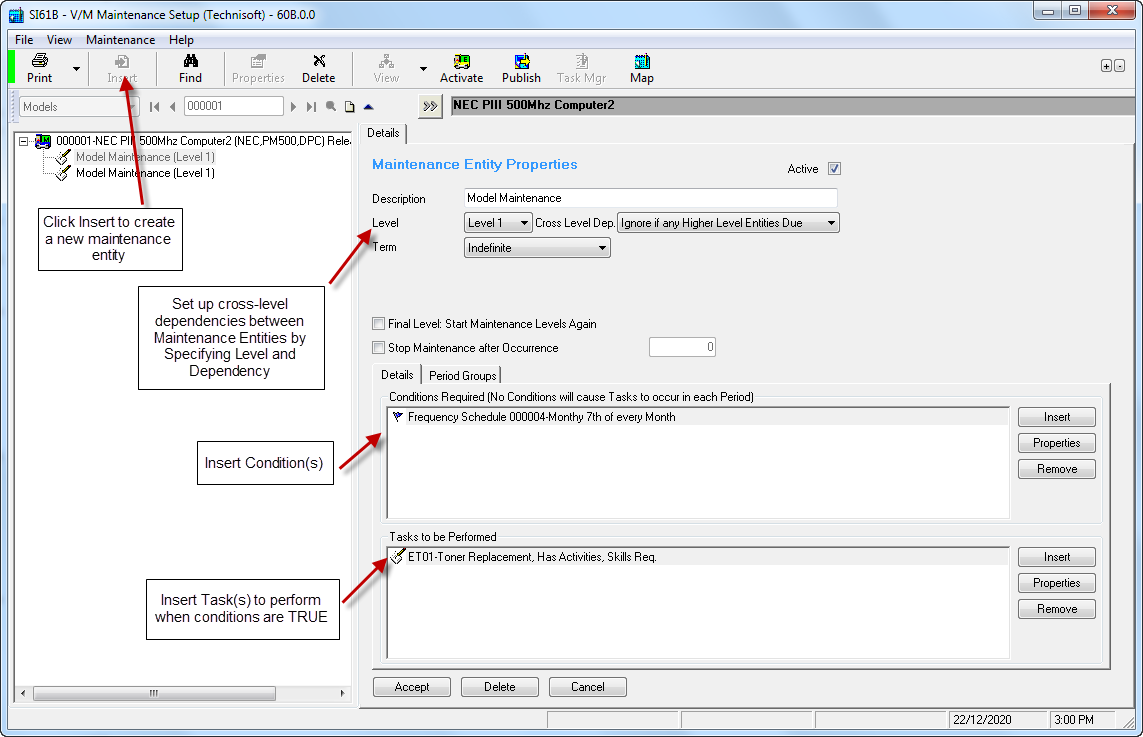

An example of a Model Maintenance Entity is shown below. Model Maintenance Entities can be published to all Equipment of that Model. The Equipment will inherit the Model Maintenance Entities, however these can be overridden if required.

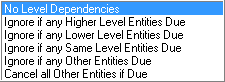

Maintenance Entities can be linked via Levels to create cross-level dependencies. This is particularly useful for isolating tasks to be completed when two entities fall at the same time. For example, when a monthly task is due and a quarterly task is due at the same time, the system can be set up so the quarterly entity ignores the monthly and only the quarterly tasks are created. In this case the Monthly Entity would be set up as Level 1 - Ignore if any higher level entities are due. The Quarterly Entity would simply be set up as a Level 2 Maintenance Entity. Therefore when Level 1 and Level 2 fall due in the same month, the Level 1 tasks would be ignored.

The following Level options are available:

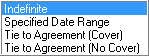

The next important setup issue to deal with is the Term of the maintenance, i.e., when the maintenance should begin and end. The following Term options are available:

From within Model Maintenance Entities this is really just a default setting and can be changed at Site/Equipment level. The recommended setting at Model level is Indefinite. That allows the user to specify a Condition to determine when the maintenance commences or simply use the Maintenance Commencement Date. Maintenance will continue indefinitely from that Commencement Date until deactivated.

The Final Level: Start Maintenance Levels Again checkbox allows for the reset of a complete maintenance cycle based on the completion of a particular level in the cycle sequence.

Example:

If a plan is setup with 250hr, 500hr, 1,000hr cycles each specified with a different level (Level 1, 2, 3 in this example), it is now possible to set the 1,000 hour plan (Level 3) to be the last level in the cycle and effect a reset back to the 250hr plan (Level 1, being the first level in the cycle), in order to repeat the maintenance sequence ad infinitum until manually stopped.

The Stop Maintenance after Occurrence option provides a mechanism to activate the Maintenance Entity once only (in the case of a new installation of equipment as a special one-off customer service function, for example) or activate it several times and then discontinue the maintenance at some future point.

The Active check box can activate or deactivate maintenance at any time.

The Most Recent Status for a new maintenance entity will be set to Pending.

Equipment can be activated and deactivated by ticking/clearing the Equipment Active check box. You can also load Model maintenance records into Equipment maintenance for an individual piece of Equipment. Refer also to Publishing Model Maintenance to Equipment.